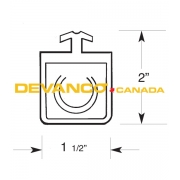

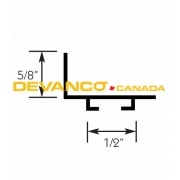

ZAP-8825-3

ZAP-8825-3

|

|

||||||

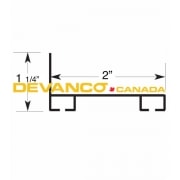

Z9963

Z9963

|

|

||||||

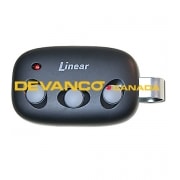

Z9403

Z9403

|

|

||||||

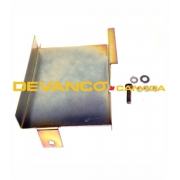

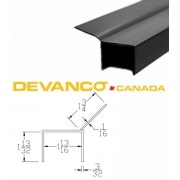

Z9211-3

Z9211-3

|

|

||||||

Z9003

Z9003

|

|

||||||

XBA13

XBA13

|

|

||||||

WKP5LM3

WKP5LM3

|

|

||||||

WKP250LM3

WKP250LM3

|

|

||||||

WINDOW-21X13

WINDOW-21X13

|

|

||||||

VS-GSLG-723

VS-GSLG-723

|

|

||||||

VME1-208-3

VME1-208-3

|

|

||||||

UTIL013

UTIL013

|

|

||||||

TRANSF143

TRANSF143

|

|

||||||

TRACKS-SET-3

TRACKS-SET-3

|

|

||||||

TRACK003

TRACK003

|

|

||||||

TRACK-2"-RAW-13

TRACK-2"-RAW-13

|

|

||||||

T-833

T-833

|

|

||||||

T-733

T-733

|

|

||||||

SRB-3

SRB-3

|

|

||||||

SPRING043

SPRING043

|

|

||||||

SPREADER003

SPREADER003

|

|

||||||

SPRAY-523

SPRAY-523

|

|

||||||

SHAFT023

SHAFT023

|

|

||||||

SGP-353-2-575/3

SGP-353-2-575/3

|

|

||||||

SGP-353-1-575/3

SGP-353-1-575/3

|

|

||||||

SESMT03

SESMT03

|

|

||||||

SELWR433

SELWR433

|

|

||||||

SEA433

SEA433

|

|

||||||

SBB-3

SBB-3

|

|

||||||

SBB-2-V3

SBB-2-V3

|

|

||||||

RS36203

RS36203

|

|

||||||

RESET003

RESET003

|

|

||||||

RELAY043

RELAY043

|

|

||||||

RADIO-EM903

RADIO-EM903

|

|

||||||

RA-AD-T3

RA-AD-T3

|

|

||||||

R5993

R5993

|

|

||||||

R5213

R5213

|

|

||||||

Q223

Q223

|

|

||||||

Q123

Q123

|

|

||||||

Q013

Q013

|

|

||||||

Q003

Q003

|

|

||||||

PRO-PL-INV-200-23

PRO-PL-INV-200-23

|

|

||||||

PRO-PL-20053

PRO-PL-20053

|

|

||||||

PRO-GHCB-30053

PRO-GHCB-30053

|

|

||||||

PRO-GHCB-20053

PRO-GHCB-20053

|

|

||||||

PRO-GHC-30053

PRO-GHC-30053

|

|

||||||

PPK3

PPK3

|

|

||||||

PHOTO-073

PHOTO-073

|

|

||||||

PCBA-PD3.3

PCBA-PD3.3

|

|

||||||

PC-3

PC-3

|

|

||||||

PBTL-3

PBTL-3

|

|

||||||

PBT-3

PBT-3

|

|

||||||

PBC-3

PBC-3

|

|

||||||

P93501100013

P93501100013

|

|

||||||

OVERLOAD003

OVERLOAD003

|

|

||||||

OCDFX3

OCDFX3

|

|

||||||

O18R1003

O18R1003

|

|

||||||

NUT013

NUT013

|

|

||||||

MX00203

MX00203

|

|

||||||

MX-00033

MX-00033

|

|

||||||

MV-00273

MV-00273

|

|

||||||

MV-00133

MV-00133

|

|

||||||

MV-00023

MV-00023

|

|

||||||

MV-00003

MV-00003

|

|

||||||

MTS3

MTS3

|

|

||||||

MTR3

MTR3

|

|

||||||

MS00003

MS00003

|

|

||||||

MPB-3

MPB-3

|

|

||||||

MP00053

MP00053

|

|

||||||

MP00013

MP00013

|

|

||||||

MOUNTSHAFT013

MOUNTSHAFT013

|

|

||||||

MOTOR403

MOTOR403

|

|

||||||

MOTOR383

MOTOR383

|

|

||||||

MOTOR273

MOTOR273

|

|

||||||

MODKIT003

MODKIT003

|

|

||||||

MOD003

MOD003

|

|

||||||

MO00003

MO00003

|

|

||||||

MM00013

MM00013

|

|

||||||

MK01563

MK01563

|

|

||||||

MK00713

MK00713

|

|

||||||

MK00643

MK00643

|

|

||||||

MK-00703

MK-00703

|

|

||||||

MK-00653

MK-00653

|

|

||||||

MK-00523

MK-00523

|

|

||||||

MK-00493

MK-00493

|

|

||||||

MK-00223

MK-00223

|

|

||||||

MK-00063

MK-00063

|

|

||||||

MK-00053

MK-00053

|

|

||||||

MK-00043

MK-00043

|

|

||||||

MK-00033

MK-00033

|

|

||||||

MK-00013

MK-00013

|

|

||||||

MJ00013

MJ00013

|

|

||||||

MJ00003

MJ00003

|

|

||||||

MI00003

MI00003

|

|

||||||

MH00043

MH00043

|

|

||||||

MH00013

MH00013

|

|

||||||

MH00003

MH00003

|

|

||||||

MG020-Y-2E-03

MG020-Y-2E-03

|

|

||||||

MG020-B-2E-03

MG020-B-2E-03

|

|

||||||

MG00013

MG00013

|

|

||||||

MF00003

MF00003

|

|

||||||

ME210-C3

ME210-C3

|

|

||||||

ME123-CA3

ME123-CA3

|

|

||||||

ME123-C3

ME123-C3

|

|

||||||

ME123-2M-BLK-RH-T3

ME123-2M-BLK-RH-T3

|

|

||||||

ME113-C3

ME113-C3

|

|

||||||

ME112-C3

ME112-C3

|

|

||||||

ME110-C3

ME110-C3

|

|

||||||

ME00003

ME00003

|

|

||||||

MD00413

MD00413

|

|

||||||

MD00093

MD00093

|

|

||||||

MD-00563

MD-00563

|

|

||||||

MD-00173

MD-00173

|

|

||||||

MD-00033

MD-00033

|

|

||||||

MD-00003

MD-00003

|

|

||||||

MCT-3

MCT-3

|

|

||||||

MB-01303

MB-01303

|

|

||||||

MB-01003

MB-01003

|

|

||||||

MATDCBB3

MATDCBB3

|

|

||||||

MASDCBB3

MASDCBB3

|

|

||||||

MAG-3

MAG-3

|

|

||||||

MADCBB3

MADCBB3

|

|

||||||

MA033

MA033

|

|

||||||

MA013

MA013

|

|

||||||

MA003

MA003

|

|

||||||

M3-3313

M3-3313

|

|

||||||

M003

M003

|

|

||||||

M-0133

M-0133

|

|

||||||

LIMIT023

LIMIT023

|

|

||||||

LEVER063

LEVER063

|

|

||||||

KSWG-0623

KSWG-0623

|

|

||||||

K94-37694-3

K94-37694-3

|

|

||||||

K77-37853

K77-37853

|

|

||||||

K77-10473

K77-10473

|

|

||||||

K76-34697-3

K76-34697-3

|

|

||||||

K75-36875-3

K75-36875-3

|

|

||||||

K75-32463

K75-32463

|

|

||||||

K75-18493

K75-18493

|

|

||||||

K74-31243

K74-31243

|

|

||||||

K74-30763

K74-30763

|

|

||||||

K72-33873

K72-33873

|

|

||||||

K72-12563

K72-12563

|

|

||||||

K72-12493

K72-12493

|

|

||||||

K32-37560-3

K32-37560-3

|

|

||||||

K23-20523

K23-20523

|

|

||||||

K21-36793

K21-36793

|

|

||||||

K19-4853

K19-4853

|

|

||||||

K12-8033

K12-8033

|

|

||||||

K11-37823

K11-37823

|

|

||||||

K10-36183

K10-36183

|

|

||||||

K093A0763

K093A0763

|

|

||||||

K07-8063

K07-8063

|

|

||||||

K07-8003

K07-8003

|

|

||||||

K002B0799-3

K002B0799-3

|

|

||||||

K001C3196-3

K001C3196-3

|

|

||||||

K-SL5851011G3

K-SL5851011G3

|

|

||||||

JA383

JA383

|

|

||||||

IS-3

IS-3

|

|

||||||

INTERFACE003

INTERFACE003

|

|

||||||

HSLG-123

HSLG-123

|

|

||||||

HAE00073

HAE00073

|

|

||||||

HAE00033

HAE00033

|

|

||||||

HAE00023

HAE00023

|

|

||||||

HAE00013

HAE00013

|

|

||||||

H14G03

H14G03

|

|

||||||

H11G03

H11G03

|

|

||||||

GRC390/315-3

GRC390/315-3

|

|

||||||

GITR-3

GITR-3

|

|

||||||

GH-353-3

GH-353-3

|

|

||||||

G3353

G3353

|

|

||||||

G3243

G3243

|

|

||||||

EP2983

EP2983

|

|

||||||

EAST/STL-E3

EAST/STL-E3

|

|

||||||

E/BLOP/123

E/BLOP/123

|

|

||||||

E/BLOP/103

E/BLOP/103

|

|

||||||

E/1929/073

E/1929/073

|

|

||||||

E/1929/023

E/1929/023

|

|

||||||

DM413

DM413

|

|

||||||

DB13

DB13

|

|

||||||

CPT215-END-KIT-T3

CPT215-END-KIT-T3

|

|

||||||

CPT210-C3

CPT210-C3

|

|

||||||

CPS-3

CPS-3

|

|

||||||

CP-SH-34-MC3

CP-SH-34-MC3

|

|

||||||

CP-MO-34-575/3

CP-MO-34-575/3

|

|

||||||

CP-HU-TC3-34-575/3

CP-HU-TC3-34-575/3

|

|

||||||

CONTACTOR043

CONTACTOR043

|

|

||||||

CONTACTOR003

CONTACTOR003

|

|

||||||

BRAKE013

BRAKE013

|

|

||||||

BRACKET003

BRACKET003

|

|

||||||

BOARD003

BOARD003

|

|

||||||

BMA3

BMA3

|

|

||||||

BK313

BK313

|

|

||||||

BK303

BK303

|

|

||||||

BG790-50-53

BG790-50-53

|

|

||||||

BG770-50-53

BG770-50-53

|

|

||||||

BEARING033

BEARING033

|

|

||||||

BCSI-PM203

BCSI-PM203

|

|

||||||

BCSI-PM03

BCSI-PM03

|

|

||||||

BCSI-HV-100-53

BCSI-HV-100-53

|

|

||||||

BCSI-HV-100-23

BCSI-HV-100-23

|

|

||||||

ZZ36767890

ZZ36767890

|

|

||||||

ZAP-AX27-VBELT

ZAP-AX27-VBELT

|

|

||||||

ZAP-8830

ZAP-8830

|

|

||||||

ZAP-8825-3-HPB

ZAP-8825-3-HPB

|

|

||||||

ZAP-8825-3

ZAP-8825-3

|

|

||||||

ZAP-8800

ZAP-8800

|

|

||||||

Z9997

Z9997

|

|

||||||

Z9967

Z9967

|

|

||||||

Z9966

Z9966

|

|

||||||

Z9963

Z9963

|

|

||||||

Z9408

Z9408

|

|

||||||

Z9405

Z9405

|

|

||||||

Z9403

Z9403

|

|

||||||

Z9401

Z9401

|

|

||||||

Z9211-3

Z9211-3

|

|

||||||

Z9211-1

Z9211-1

|

|

||||||

Z9202

Z9202

|

|

||||||

Z9006

Z9006

|

|

||||||

Z9005

Z9005

|

|

||||||

Z9004

Z9004

|

|

||||||

Z9003-QUIET

Z9003-QUIET

|

|

||||||

Z9003-MAX

Z9003-MAX

|

|

||||||

YSG12-24LED

YSG12-24LED

|

|

||||||

YSG115-LED

YSG115-LED

|

|

||||||

XT2563-CUT

XT2563-CUT

|

|

||||||

XT2563-00-W

XT2563-00-W

|

|

||||||

XT-1H

XT-1H

|

|

||||||

XLSOLARCONTUL

XLSOLARCONTUL

|

|

||||||

XBA4

XBA4

|

|

||||||

XBA3HF

XBA3HF

|

|

||||||

XBA15

XBA15

|

|

||||||

WSL-1

WSL-1

|

|

||||||

WS-UHF-0-0

WS-UHF-0-0

|

|

||||||

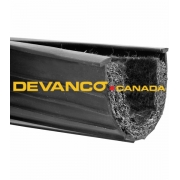

WS-BOT-PVC2-09

WS-BOT-PVC2-09

|

|

||||||

WRW

WRW

|

|

||||||

WRAES

WRAES

|

|

||||||

WR2

WR2

|

|

||||||

WPS-1H-110V

WPS-1H-110V

|

|

||||||

WOR

WOR

|

|

||||||

WKP5LM3

WKP5LM3

|

|

||||||

WKP250LM3

WKP250LM3

|

|

||||||

WINDOW-21X13

WINDOW-21X13

|

|

||||||

WHTG-HINGE-TRUSS

WHTG-HINGE-TRUSS

|

|

||||||

WHITING-DOOR

WHITING-DOOR

|

|

||||||

WHITING-ALUMCLAD

WHITING-ALUMCLAD

|

|

||||||

WGEC24-75WR

WGEC24-75WR

|

|

||||||

WEL-200

WEL-200

|

|

||||||

WE684

WE684

|

|

||||||

WD-334642

WD-334642

|

|

||||||

WD-327310

WD-327310

|

|

||||||

WD-309961

WD-309961

|

|

||||||

WD-309884

WD-309884

|

|

||||||

WD-260600

WD-260600

|

|

||||||

WB-350

WB-350

|

|

||||||

WB-300

WB-300

|

|

||||||

WASHER035

WASHER035

|

|

||||||

VWS-34-ZINC

VWS-34-ZINC

|

|

||||||

VWS-34-WHITE

VWS-34-WHITE

|

|

||||||

VWS-34-SANDSTONE

VWS-34-SANDSTONE

|

|

||||||

VWS-34-MED-OAK

VWS-34-MED-OAK

|

|

||||||

VWS-34-GOLD-OAK

VWS-34-GOLD-OAK

|

|

||||||

VWS-34-DARK-OAK

VWS-34-DARK-OAK

|

|

||||||

VWS-34-DARK-BRWN

VWS-34-DARK-BRWN

|

|

||||||

VWS-34-CREAM

VWS-34-CREAM

|

|

||||||

VWS-34-CHRY-OAK

VWS-34-CHRY-OAK

|

|

||||||

VWS-34-CHARCOAL

VWS-34-CHARCOAL

|

|

||||||

VWS-34-BROWN

VWS-34-BROWN

|

|

||||||

VWS-34-BRONZE

VWS-34-BRONZE

|

|

||||||

VWS-34-BLACK

VWS-34-BLACK

|

|

||||||

VTS-GAREX-P/FOOT

VTS-GAREX-P/FOOT

|

|

||||||

VS-GSLG-723

VS-GSLG-723

|

|

||||||

VME1-230-1

VME1-230-1

|

|

||||||

VME1-208-3

VME1-208-3

|

|

||||||

VL-450-LED

VL-450-LED

|

|

||||||

VKP1-LM

VKP1-LM

|

|

||||||

VGD-RB-1/2T-10

VGD-RB-1/2T-10

|

|

||||||

VFOH5011

VFOH5011

|

|

||||||

VBELT_5L370

VBELT_5L370

|

|

||||||

VBELT_5L350

VBELT_5L350

|

|

||||||

VBELT_5L345

VBELT_5L345

|

|

||||||

VBELT_5L340

VBELT_5L340

|

|

||||||

VBELT_4L390

VBELT_4L390

|

|

||||||

VBELT_4L370

VBELT_4L370

|

|

||||||

VBELT_4L360

VBELT_4L360

|

|

||||||

VBELT_4L355

VBELT_4L355

|

|

||||||

VBELT_4L340

VBELT_4L340

|

|

||||||

VBELT_4L310

VBELT_4L310

|

|

||||||

VBELT_4L300

VBELT_4L300

|

|

||||||

VBELTB30

VBELTB30

|

|

||||||

VBELTB29

VBELTB29

|

|

||||||

V3564-PER-FOOT

V3564-PER-FOOT

|

|

||||||

V3564-00-W-200

V3564-00-W-200

|

|

||||||

V3563-00-W-200

V3563-00-W-200

|

|

||||||

UR2

UR2

|

|

||||||

UNI-100-82

UNI-100-82

|

|

||||||

UNI-100-162

UNI-100-162

|

|

||||||

UNI-100-142

UNI-100-142

|

|

||||||

UNI-100-122

UNI-100-122

|

|

||||||

UNI-100-102

UNI-100-102

|

|

||||||

UN201

UN201

|

|

||||||

ULTRA-II-D-TEK

ULTRA-II-D-TEK

|

|

||||||

ULTRA-DIN

ULTRA-DIN

|

|

||||||

ULT-PLG-D-TEK

ULT-PLG-D-TEK

|

|

||||||

ULT-MVP-2-D-TEK

ULT-MVP-2-D-TEK

|

|

||||||

ULT-MVP

ULT-MVP

|

|

||||||

UCFL-1-1/4

UCFL-1-1/4

|

|

||||||

TXTA-KYPD

TXTA-KYPD

|

|

||||||

TXTA-200

TXTA-200

|

|

||||||

TVB636-11SF

TVB636-11SF

|

|

||||||

TVB624-11SF

TVB624-11SF

|

|

||||||

TVB620-11SF

TVB620-11SF

|

|

||||||

TVB436-11SF

TVB436-11SF

|

|

||||||

TVB424-11SF

TVB424-11SF

|

|

||||||

TVB420-11SF

TVB420-11SF

|

|

||||||

TUBE_SHAFT_17-STL

TUBE_SHAFT_17-STL

|

|

||||||

TTC-MODULE

TTC-MODULE

|

|

||||||

TS150

TS150

|

|

||||||

TS-15

TS-15

|

|

||||||

TS-1-255-GALV-KEY

TS-1-255-GALV-KEY

|

|

||||||

TS-1-207-GALV-KEY

TS-1-207-GALV-KEY

|

|

||||||

TS-1-183-GALV-KEY

TS-1-183-GALV-KEY

|

|

||||||

TS-1-168-GALV-KEY

TS-1-168-GALV-KEY

|

|

||||||

TS-1-159-GALV-KEY

TS-1-159-GALV-KEY

|

|

||||||

TS-1-135-GALV-KEY

TS-1-135-GALV-KEY

|

|

||||||

TS-1-129-GALV-KEY

TS-1-129-GALV-KEY

|

|

||||||

TS-1-111-GALV-KEY

TS-1-111-GALV-KEY

|

|

||||||

TRACKS-SET-3

TRACKS-SET-3

|

|

||||||

TRACK-SET-3-134-8

TRACK-SET-3-134-8

|

|

||||||

TRACK-SET-3-134-12

TRACK-SET-3-134-12

|

|

||||||

TRACK-SET-2STD-8

TRACK-SET-2STD-8

|

|

||||||

TRACK-SET-2STD-7

TRACK-SET-2STD-7

|

|

||||||

TRACK-SET-2STD-14

TRACK-SET-2STD-14

|

|

||||||

TRACK-SET-2STD-12

TRACK-SET-2STD-12

|

|

||||||

TRACK-SET-2STD-10

TRACK-SET-2STD-10

|

|

||||||

TRACK-SET-2LHR-R

TRACK-SET-2LHR-R

|

|

||||||

TRACK-SET-2LHR-F

TRACK-SET-2LHR-F

|

|

||||||

TRACK-SET-2LH-138

TRACK-SET-2LH-138

|

|

||||||

TRACK-SET-2-138-8

TRACK-SET-2-138-8

|

|

||||||

TRACK-SET-2-138-7

TRACK-SET-2-138-7

|

|

||||||

TRACK-SET-2-134-8

TRACK-SET-2-134-8

|

|

||||||

TRACK-SET-2-134-7

TRACK-SET-2-134-7

|

|

||||||

TRACK-GUARD48-NP

TRACK-GUARD48-NP

|

|

||||||

TRACK-GUARD-72

TRACK-GUARD-72

|

|

||||||

TRACK-GUARD-60

TRACK-GUARD-60

|

|

||||||

TRACK-GUARD-48

TRACK-GUARD-48

|

|

||||||

TRACK-GUARD-36

TRACK-GUARD-36

|

|

||||||

TRACK-GUARD-24

TRACK-GUARD-24

|

|

||||||

TRACK-3"-RAW-24

TRACK-3"-RAW-24

|

|

||||||

TRACK-3"-RAW-16

TRACK-3"-RAW-16

|

|

||||||

TRACK-3"-RAW-14

TRACK-3"-RAW-14

|

|

||||||

TRACK-3"-RAW-12

TRACK-3"-RAW-12

|

|

||||||

TRACK-2"-RAW-13

TRACK-2"-RAW-13

|

|

||||||

TR-GUARD

TR-GUARD

|

|

||||||

TOP-BK-PCG

TOP-BK-PCG

|

|

||||||

TODCO-DOOR-USA

TODCO-DOOR-USA

|

|

||||||

TNR-HDXL-CUSTOM

TNR-HDXL-CUSTOM

|

|

||||||

TN29C

TN29C

|

|

||||||

TL-5000

TL-5000

|

|

||||||

TL-36ML-BLUE

TL-36ML-BLUE

|

|

||||||

TDC7S1BMC

TDC7S1BMC

|

|

||||||

TDC7-8

TDC7-8

|

|

||||||

TDC7-14

TDC7-14

|

|

||||||

TDC22X1BMC

TDC22X1BMC

|

|

||||||

TDC12X1BMC

TDC12X1BMC

|

|

||||||

TDC12S1BMC

TDC12S1BMC

|

|

||||||

TDC1222-8

TDC1222-8

|

|

||||||

TDC1222-20

TDC1222-20

|

|

||||||

TDC1222-14

TDC1222-14

|

|

||||||

TD-134

TD-134

|

|

||||||

TCG-2

TCG-2

|

|

||||||

TCBOS-311

TCBOS-311

|

|

||||||

TCBOD-321

TCBOD-321

|

|

||||||

TC3-411

TC3-411

|

|

||||||

TC2

TC2

|

|

||||||

TC134-9

TC134-9

|

|

||||||

TC134-8

TC134-8

|

|

||||||

TC134-18

TC134-18

|

|

||||||

TC134-16

TC134-16

|

|

||||||

TC134-14

TC134-14

|

|

||||||

TC134-12

TC134-12

|

|

||||||

TC134-10

TC134-10

|

|

||||||

TC1

TC1

|

|

||||||

TB612-36SF

TB612-36SF

|

|

||||||

TB612-24SF

TB612-24SF

|

|

||||||

TB612-18SF

TB612-18SF

|

|

||||||

TB612-14SF

TB612-14SF

|

|

||||||

TB610-36SF

TB610-36SF

|

|

||||||

TB610-24SF

TB610-24SF

|

|

||||||

TB610-18SF

TB610-18SF

|

|

||||||

TB610-14SF

TB610-14SF

|

|

||||||

TB412-36SF

TB412-36SF

|

|

||||||

TB412-24SF

TB412-24SF

|

|

||||||

TB412-18SF

TB412-18SF

|

|

||||||

TB412-14SF

TB412-14SF

|

|

||||||

TB410-36SF

TB410-36SF

|

|

||||||

TB410-24SF

TB410-24SF

|

|

||||||

TB410-18SF

TB410-18SF

|

|

||||||

TB410-14SF

TB410-14SF

|

|

||||||

TB406-36SF

TB406-36SF

|

|

||||||

TB406-24SF

TB406-24SF

|

|

||||||

Your Search

Your Search